CP-992 Organophilic clay

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

The organic bentonite produced by Camp Shinning is suitable for drilling fluids used in complex formations such as shale oil and gas, deep-sea deep wells, and ultra-deep wells for energy extraction.

Therefore, organic bentonite is an important component in drilling fluid formulations, used to improve the dynamic shear force of the mud, reduce filtration loss, stabilize the system, and enhance the ability of the mud to suspend and carry rock cuttings, clean the wellbore, and protect the wellbore.

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

CP-982 Organophilic Clay is an amine treated bentonite with a moderate temperature performance.

CP-150 Organophilic Clay is a self-activating organoclay that disperses easily and performs well in diesel, low aromatic mineral oil, modified vegetable oil, and synthetic base fluid formulations.

Bentonite clay for drilling: Are you looking for an addition to help your products perform better?

Take a look at Organoclay. Our addition can aid in rheological, thickening, thixotropic, and anti-settling qualities. With our additive, your products will perform better than ever before.

With our additive, you may improve your suspension.

CP-10 organoclay is a rheological additive made of organoclay. It is used in non-polar to moderately polar aliphatic and other solvent systems

CP-MPZ organoclays is an modified bentonite that is used in solvent and resin systems ranging from non-polar to highly polar.

The CP-MPS rheology modifier is a type of organo clay rheological additive that is used in solvent and resin systems ranging from non-polar to high polarity.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-EW Organoclay for Water Based paint. It is primarily employed in water borne paint systems,such as latex paint. So it is a good water based additive in paints,coatings,grease etc.

CP-EWS Modified bentonite It is employed in a water-borne coatings system. CP-EWS organoclay outperforms CP-EW in terms of thixotropy, transparence, and dispersion.

CP-WBS Rheology Modifier is rheological modified bentonite. It is mostly employed in water-borne systems.

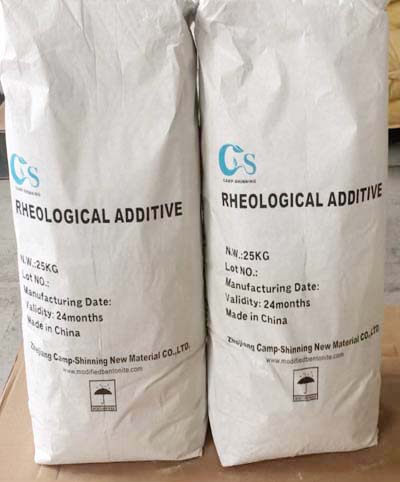

The Bentonite clay for drilling Organoclay bentonite | Organophilic clay -specialized Zhejiang Camp-Shinning New Material CO.,LTD. and Hangzhou Camp-Shinning CO.,LTD. are subsidiaries of Camp-Shinning.

Camp-shinning concentrated on high value-added, high-technology organo bentonite series products, particularly in research, development, manufacturing, and sales of organic (solvent based organoclay) and inorganic bentonite (water based organoclay).

Our Organophilic bentonite clay finds widespread application in oil drilling mud, paint, coating, lubricating grease, adhesive, construction mortar, cosmetics, and waste water treatment, among other applications. A group of world-class professional users and distributors, such as SUN CHEMICAL,,SIEGWERK,LEHMANN &VOsS, and others, have acknowledged our dependable quality.

Current annual production of organic bentonite clay | organoclay is 20,000 metric tons, while refined bentonite production is 15,000 metric tons.

Our ISO 9001 quality system certification and IS014001 environmental management system certification, as well as our own mine with superior ore quality and production of proprietary technology, ensure the long-term quality and supply stability of our Organoclay bentonite | Organophilic clay.

Our mission is to provide users with superior Organoclay bentonite | Organophilic clay and services and to collaborate with them to achieve success and glory.

Internet address: https://www.rheologymodifiers.com/ and email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Bentonite clay for drilling

Bentonite clay for drilling

This article discusses the CP-982 organophilic clay and its effects on gasoil-based drilling muds. It also explains how organophilic clay is made. The findings of these studies are applicable to drilling fluid additives.

Bentonite clay for drilling : Organophilic clay CP-992

Increased amounts of CP-992 organophilic clay in drilling muds have been shown to improve drilling fluid stability both below and above the critical dose. This increase is caused by the formation of a three-dimensional network of flocculated particles within the drilling mud’s external phase. This network is distinguished by double-layer repulsion and increased yield stress.

To increase the stability of gasoil-based drilling muds, CP-992 organophilic clay was added in the study. This additive improved yield stress, viscoelasticity, and thixotropic properties.

The viscosifier and gelling agent CP-992 organophilic clay is used in oil-based and synthetic-based drilling fluids. It is bentonite that has been amine-treated. It improves the carrying capacity of drilling fluids, aids in filtercake formation, and is useful in a variety of specialty applications. The use of CP-992 organophilic clay in drilling fluids, on the other hand, should be based on the recommended concentration and dilution rates.

Temperature influences the viscosity of oil-based drilling fluids.

A recent study discovered that temperature influences the electrical resistivity of drilling mud.

Organophilic clay preparation :Bentonite clay for drilling

Dry-processed organophilic clays differ from those modified by aqueous systems.

Organophilic clays are made by reacting organophilic compounds in an aqueous dispersion at 100 to 120 degrees Fahrenheit. To create a stable compound, the exact proportions of clay and quaternary ammonium salt must be determined. After that, the modified clays are filtered and dried in warm air. They are then ground to the desired mesh size.

In drilling fluids, organophilic clays are frequently used as primary viscosifiers. However, under certain conditions, they are susceptible to stratification and have relatively slow chemical-reaction rates. They also have high pressure spikes and relatively high equivalent circulating densities. Despite these characteristics, they have poor temperature stability. A temperature that is too high will cause thermal degradation of the colloids, while a temperature that is too low may cause excessive viscosity.

Organophilic clays are rheological additives that can be used in oil base drilling fluids or invert emulsion drilling fluids. The compositions can be made using traditional drilling fluid preparation methods, or they can be thickened with organophilic clay gellant. The amounts of additives used are typically small – typically 0.01% to 5% of the total weight – and sufficient to produce the desired rheological properties.

Furthermore, it demonstrated a good ability to suspend cuttings during pressure and temperature changes.

Drilling fluids based on gasoil have a variety of properties, including viscosity and clogging power. Oil-based drilling muds, on the other hand, are notorious for their chemical and rheological instability. Oil-based drilling muds use organophilic clay to increase viscosity and improve rheological properties to overcome these challenges.

Organophilic clays are chemically treated clays that dissolve easily in water. This makes them more suitable for drilling through rock and hard surfaces. These additives improve drilling efficiency and protect equipment from corrosion. These additives, in addition to being useful in drilling fluids, also serve as coatings for oil-based drilling fluids.

Several studies have shown that CP-992 organophilic clay improves the stability of gasoil-based drilling fluids. It also increases the fluid’s yield stress and viscoelasticity, making it more shear-thin.

Bentonite clay for drilling

The effects of the organophilic clay CP-992 on the rheological properties of gasoil-based drilling muds

CP-992 is an organophilic clay that increases the viscoelasticity of drilling mud based on gasoil. Due to a continuous hydration reaction between the clay particles, the addition of CP-992 increases the viscoelasticity of the mud. As a result, the mud’s critical shear stress rises.

The proportion of CP-992 organophilic clay in drilling muds determines its thixotropic behavior. CP-992 reduces the interfacial tension between water and gasoil, allowing gasoil-based drilling muds to be more stable.

Oil-based muds have numerous advantages over water-based drilling fluids. They have excellent lubricity. In addition to these benefits, oil-based drilling muds can prevent water from penetrating the formation. As a result, they can help with in-situ core recovery. Furthermore, unlike water-based muds, oil-based drilling muds do not suffer from swelling and sloughing in hydrous clays.

Bentonite clay for drilling

The combination of CP-992 organophilic clay and white oils can improve the fluid’s rheological properties, increase lubricity, and reduce drilling equipment wear and tear. The resulting emulsions are environmentally friendly and biodegradable, and they can be used in place of traditional oil muds. The emulsions can be tailored to improve lubricity and stability.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-180 organoclay is an organo clay rheological additive (modified montmorillonite) designed specifically for use in solvent-based systems

CP-34 organoclay is a modified bentonite that has been specifically designed for use in solvent-based systems.

CP-EDS modified bentonite is a kind of organo clay rheological additive. It is used in systems of medium polarity and high polarity system.

Bentonite clay for drilling , organo bentonite drilling , bentonite clay drilling mud