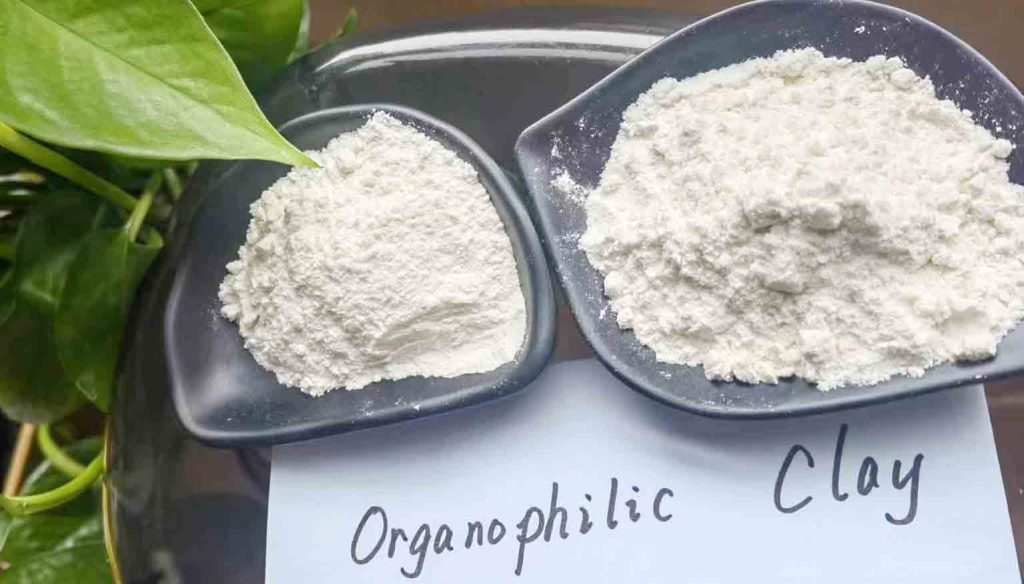

Organoclay for Grease Supplier in China | Bentonite CP-40

Organoclay for Grease : We strongly recommend that you use organo clay bentonite in lubricating grease. Organophilic clay can actively improve the thickening performance and anti settling property of lubricating oil.

At the same time, its rheological property is also very outstanding. If you have a desire for suspension and thixotropy, Camp Shinning can bring you unexpected results on organoclays in the formulation of lubricating grease.

Organoclay for Grease Supplier in China

Organoclay for grease is a type of clay that has been modified with organic molecules, which allows Organoclay for Grease to be used as a rheology modifier in lubricating grease. There are several advantages to using organoclay in grease formulations:

CP-180 Bentonite grease

CP-EDS organoclay for grease

CP-EZ10Bentonite for lubricant

Organoclay for Grease Manufacturer in China

Today we will mainly talk about the application of organoclay bentonite in lubricating grease. What advantages will organoclay bring to you?

As we all know, organic clay is a kind of clay modified by organic molecular bentonite, This makes it used as a rheological rheology modifier in lubricating grease, and the use of organic clay, that is, rheological additive, in lubricating grease formulation. It has several very obvious advantages, which we will illustrate one by one.

Organoclay for Grease advantages

1, First of all, organo clay can effectively improve the stability of thickened rheological agent, because the more effective thickener in the organic bentonite grease formula can maintain good stability within a wide temperature range, which enables it to provide stable grease performance during the service life of the grease.

2, In terms of water resistance, organophilic clay bentonite shows better water resistance in grease. When he asked grease about its exposure to water or high humidity applications, it may be a problem, but it helps to extend the service life of grease and improve its performance.

3, Enhance the bearing capacity of lubrication. When organoclays is applied to lubricating grease, its bearing capacity can be significantly improved, so that it can effectively protect the objects it uses under heavy load, such as bearings and other parts.

4, The application of organic bentonite in lubricating grease is to improve the shear stability, which is very important for the application of lubricating grease to withstand high shear stress, and will help to improve the service life and performance of lubricating grease.

5, It can improve the compatibility with other additives.

In the whole formula, that is to say, when you add organo clay bentonite to the grease formula, it can effectively make other additives more compatible with the whole formula, such as antioxidants, polar additives and anti-corrosion agents.

This is one of the attractive options for configuring multi-functional grease.

In conclusion, the use of organic clay in grease formulation can bring you a series of unexpected benefits.

I don’t know. Organoclay bentonite has played a positive role in enhancing the stability of its real worry and thickener, improving its water resistance, enhancing its bearing capacity, enhancing its shear stability and compatibility with additives in other formulas.

As for organo clay bentonite, the total amount used in grease is 0.2%~4%. You can test the actual amount demand in your entire formula through experiments. Our information is for your reference only.

Of course, there is no doubt that the improvement of thixotropy, rheological properties and anti settling properties brought by organophilic clay bentonite to grease formula, These are positive and meaningful for grease formulation.

Although organic bentonite has a wide range of applications, it still plays an extremely important role in the current application field of grease, especially in high-temperature resistant grease.

First of all, organic bentonite is used as a thickener in grease. Its high temperature resistance is obvious. It can have a dropping point as high as 250°C and can form relatively good high radiation resistance.

This is why our organic bentonite Bentonite can be used to prepare high-temperature greases.

We have repeatedly emphasized that if you want to obtain lubricants with ideal performance, you must add a gene activator when using organic bentonite, which can achieve the best dispersion effect in the entire formula.

So the main polar activators currently on the market are methanol ethanol propylene carbonate, acetone, etc., and our most recommended and most stable one is propylene carbonate.

As the polar activator of your formula, this is the first choice.

Now we will tell you how to add organic bentonite clay.

1),The first step is to heat the oil to 60~80℃.

2),Step 2: Stir constantly and add organic bentonite at the same time, usually between 6% and 15% of the entire formula. We recommend that the mixing time for this ceramic tile is ideally 15 to 20 minutes.

3),The third step is to add the ultimate activator, then we recommend that you use propylene carbonate which is ideal.

4),The 4 step is to grind continuously at high speed.

5),The 5 step is to package it and evacuate the air inside.

The above 5 steps are how you directly add organic bentonite. Generally, it is recommended that you use this method when using our highly polar organic bentonite.

For most models, we still It is recommended that you use the pre-gel method to operate, which will make you feel better and better performance.

We will also explain to you here the advantages of organic bentonite when applied to lubricants. The main obvious ones are the following:

1) If you make pre-gel, for organic bentonite, even if the lubricating oil is at low temperature, it can still maintain relatively good lubricity.

2) Anti-bleeding is a particularly obvious feature of pre-gel lubricants.

3) Very good water resistance and good thickening properties.

We generally recommend that you use our modified bentonite clay to thicken mineral lubricants or synthetic oils.

We must clearly point out that Carnation’s organic bentonite has good heat resistance as well as mechanical and colloidal stability in greases.

Characteristics of organic bentonite grease:

1) First of all, organic bentonite can be used in high-temperature grease. For example, organic bentonite can still exert stable performance at around 180°C. In other words, organobentonite has high temperature stability.

2) In some low-temperature greases, according to the low-temperature properties of different base oils, the dosage of our organic bentonite will be adjusted to make its thickening effect meet the ideal requirements.

3), Bentonite has good anti-corrosion properties against the corrosion of metal surfaces in grease. We also recommend that you add anti-rust agents when producing grease.

4), in order to make the gel effect of lubricating ester good, we recommend that you use different organic bentonite models to match the corresponding base oil, which will improve its wear resistance and friction resistance.

We hereby state that our organic bentonite can guarantee good operation within the temperature range of 0~180℃.

We generally require the moisture in organic bentonite to be within 3.5%.

Polar additives should not be anhydrous. Generally, a polar activator content of 95% is better.

Pls fill the sheet and contact us now

Organoclay for Grease

Organoclay for Grease

For more details about the application of organic bentonite to lubricating grease, if you are still confused, you can contact our sales or technical department directly, and we will share our experience with our end users in a timely manner, which will greatly save you the process and time to explore this matter.

To sum up, our organic bentonite is applied to lubricating grease. Its role is to improve the thixotropy, rheological property, anti settling property of the entire formula and its suspension property.

Organoclay for Grease