CP-992 Organophilic clay

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

Bentonite clay for well drilling: The main goal of using organic bentonite clay in drilling fluid is to achieve stable wellbore in controlling the viscosity of the drilling fluid and suspending rock cuttings.

The ultimate goal is to achieve the ability to clean the wellbore and protect tight sealing. Therefore, in the oil and gas drilling industry, organophilic clay bentonite has become an essential drilling additive.

OrganoBentonite can suspend rock debris and weight materials, viscosity provides hydrostatic pressure to stabilize the wellbore.

At the same time, Organo clay bentonite can also filter and control, because bentonite clay gel forms a filter cake on the well wall to control the fluid loss to the permeable rock stratum.

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

CP-982 Organophilic Clay is an amine treated bentonite with a moderate temperature performance.

CP-150 Organophilic Clay is a self-activating organoclay that disperses easily and performs well in diesel, low aromatic mineral oil, modified vegetable oil, and synthetic base fluid formulations.

Bentonite clay for well drilling: Are you looking for a product to help you optimize your drilling process? Look at our organoclay! It is a thickening and stabilizing ingredient for drilling fluid, resulting in a smoother, more efficient operation. It not only works wonderfully, but it is also environmentally benefi

CP-10 organoclay is a rheological additive made of organoclay. It is used in non-polar to moderately polar aliphatic and other solvent systems

CP-MPZ organoclays is an modified bentonite that is used in solvent and resin systems ranging from non-polar to highly polar.

The CP-MPS rheology modifier is a type of organo clay rheological additive that is used in solvent and resin systems ranging from non-polar to high polarity.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-EW Organoclay for Water Based paint. It is primarily employed in water borne paint systems,such as latex paint. So it is a good water based additive in paints,coatings,grease etc.

CP-EWS Modified bentonite It is employed in a water-borne coatings system. CP-EWS organoclay outperforms CP-EW in terms of thixotropy, transparence, and dispersion.

CP-WBS Rheology Modifier is rheological modified bentonite. It is mostly employed in water-borne systems.

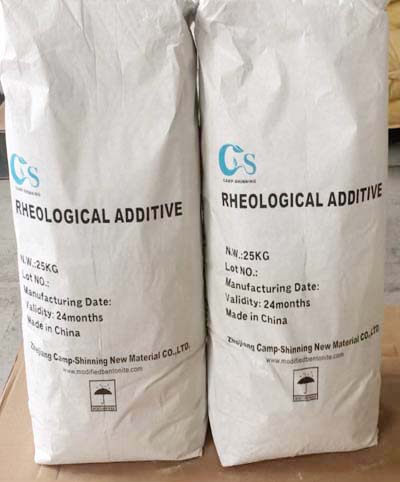

The Organoclay bentonite | Organophilic clay -specialized Zhejiang Camp-Shinning New Material CO.,LTD. and Hangzhou Camp-Shinning CO.,LTD. are subsidiaries of Camp-Shinning.

Camp-shinning concentrated on high value-added, high-technology organo bentonite series products, particularly in research, development, manufacturing, and sales of organic (solvent based organoclay) and inorganic bentonite (water based organoclay).

Our Organophilic bentonite clay finds widespread application in oil drilling mud, paint, coating, lubricating grease, adhesive, construction mortar, cosmetics, and waste water treatment, among other applications. A group of world-class professional users and distributors, such as SUN CHEMICAL,,SIEGWERK,LEHMANN &VOsS, and others, have acknowledged our dependable quality.

Current annual production of organic bentonite clay | organoclay is 20,000 metric tons, while refined bentonite production is 15,000 metric tons.

Our ISO 9001 quality system certification and IS014001 environmental management system certification, as well as our own mine with superior ore quality and production of proprietary technology, ensure the long-term quality and supply stability of our Organoclay bentonite | Organophilic clay.

Our mission is to provide users with superior Organoclay bentonite | Organophilic clay and services and to collaborate with them to achieve success and glory.

Internet address: https://www.rheologymodifiers.com/ and email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Bentonite clay for well drilling

Organoclay bentonite is a highly effective oil thickener with numerous advantages. These include oil adsorption, hydrophobic structure, and non-aqueous dispersion. It may also reduce costs for refineries and other oil and gas companies. It is also an excellent choice in flood-prone areas, particularly those prone to saline water intrusion.

Bentonite clay for well drilling

Organoclay is a phyllosilicate that has been modified from naturally occurring clay minerals. It retains its phyllosilicate lamellar structure, but its molecular structure has been altered by the covalent addition of organic moieties. It is a versatile material with a high surface area whose properties make it an effective viscosifier in oil-based drilling fluids.

High-speed shear dispersion is required to create an organoclay gel. To increase the viscosity of the gel, a fermentation activator can be added in some cases. Thixotropy, thermal stability, and dispersibility are among the properties of organoclays bentonite gels. The solution’s composition is important because it influences the gel’s dispersibility, thermal stability, and strength. A gel requires a dispersant with a low molecular weight that can penetrate the interlayers. It lifts and embeds organic cations, increasing layer spacing and unit cell volume.

This enables them to investigate the adsorption potential of organoclay bentonite. Following the synthesis, the surfactant intercalation must be confirmed. Bentonite clay for well drilling os recommended you.

Different methods of modification can be used to create organoclay bentonite.

Bentonite clay for well drilling

Organoclay is a clay that has been modified with cationic surfactants and is extremely effective at removing organic carbon from soil.

Organoclay has numerous applications, ranging from filtration to paints and pharmaceutical formulations.

Organoclay is a versatile material that is used to remove organic contaminants from soil and water. Because of its properties, it is an excellent pretreatment for Granular Activated Carbon. It also aids in reducing cap thickness, thereby extending cap life and lowering overall costs.

Bentonite clay for well drilling

Organoclay bentonite is an important mineral for pollutant adsorption. This low-cost mineral has been used in a variety of applications, including underground storage tank liners, slurry walls, and landfill liners.

The study found that increasing the agitation time increases the bentonite’s adsorptive ability.

Organoclay bentonite is a mineral made of organic clay that has several properties that make it an excellent rheological additive. It can bind oils and is very effective at removing them from water-based wastewaters. It can also suspend a variety of materials. This organic clay is commonly used as an additive in paint coatings and oil drilling fluids.

Organoclays are made by combining bentonite and quaternary ammonium compounds. The basal spacing and particle size of the organoclay are determined by the chain length of the quaternary ammonium compounds. Carbon content is another important factor that influences bulk density.

Organoclay bentonite is a mineral that is extremely absorbent. It can absorb up to 40% of moisture and then release it through a process known as precipitation. As a result, the particles emitted by the mineral are extremely small. This must be taken into account when designing a plant.

Bentonite clay for well drilling

Organoclay is a mineral that can be used to thicken water-oil mixtures. Several studies have been conducted to determine this mineral’s effectiveness as an oil-removal agent. The mineral was dispersed on the surface of wastewaters and observed for its ability to adsorb oil in these studies.

Bentonite is used to make organoclay. Its chemical composition and physical properties make it an excellent candidate for oil removal. Organoclays are extremely porous and absorb a lot of oil and water. They are also resistant to thermal and chemical deterioration.

Modifying bentonite with quaternary amines yields organoclay. As a result, the equivalent circulating density is high. Organoclay is also prone to stratification and has a slow chemical reaction time. The main disadvantage of organoclay is that it is expensive due to the chemical reaction time, and its temperature range is limited. Colloidal thermal degradation can occur at high temperatures, whereas excessive viscosity can occur at low temperatures.

Soaps, emulsions, and paints frequently contain organoclay bentonite. Its distinct properties make it suitable for a wide range of applications. Bentonite is a naturally occurring mineral found in the earth. It is typically found in soils with a moisture content of 30%.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-180 organoclay is an organo clay rheological additive (modified montmorillonite) designed specifically for use in solvent-based systems

CP-34 organoclay is a modified bentonite that has been specifically designed for use in solvent-based systems.

CP-EDS modified bentonite is a kind of organo clay rheological additive. It is used in systems of medium polarity and high polarity system.

Bentonite clay for well drilling