CP-992 Organophilic clay

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

Bentonite clay suppliers: When organic bentonite clay is used in oil field drilling, it can achieve good dispersion in the shortest time under low shear conditions. It is more suitable for high-performance viscosity enhancers of mineral oil, synthetic oil, or low aromatic base oil. In terms of price, it is more cost-effective, with ideal yield value and viscosity. At the same time, it can provide good suspension for the entire formula.

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

CP-982 Organophilic Clay is an amine treated bentonite with a moderate temperature performance.

CP-150 Organophilic Clay is a self-activating organoclay that disperses easily and performs well in diesel, low aromatic mineral oil, modified vegetable oil, and synthetic base fluid formulations.

Bentonite clay suppliers: Looking for a more effective method to thicken and gel drilling fluids? Our organoclay Bentonite clay providers can help you complete your project successfully. It disperses smoothly and fast in various sorts of base oils, so you don’t have to wait long to see results. You will appreciat

CP-10 organoclay is a rheological additive made of organoclay. It is used in non-polar to moderately polar aliphatic and other solvent systems

CP-MPZ organoclays is an modified bentonite that is used in solvent and resin systems ranging from non-polar to highly polar.

The CP-MPS rheology modifier is a type of organo clay rheological additive that is used in solvent and resin systems ranging from non-polar to high polarity.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-EW Organoclay for Water Based paint. It is primarily employed in water borne paint systems,such as latex paint. So it is a good water based additive in paints,coatings,grease etc.

CP-EWS Modified bentonite It is employed in a water-borne coatings system. CP-EWS organoclay outperforms CP-EW in terms of thixotropy, transparence, and dispersion.

CP-WBS Rheology Modifier is rheological modified bentonite. It is mostly employed in water-borne systems.

The Organoclay bentonite | Organophilic clay -specialized Zhejiang Camp-Shinning New Material CO.,LTD. and Hangzhou Camp-Shinning CO.,LTD. are subsidiaries of Camp-Shinning.

Camp-shinning concentrated on high value-added, high-technology organo bentonite series products, particularly in research, development, manufacturing, and sales of organic (solvent based organoclay) and inorganic bentonite (water based organoclay).

Our Organophilic bentonite clay finds widespread application in oil drilling mud, paint, coating, lubricating grease, adhesive, construction mortar, cosmetics, and waste water treatment, among other applications. A group of world-class professional users and distributors, such as SUN CHEMICAL,,SIEGWERK,LEHMANN &VOsS, and others, have acknowledged our dependable quality.

Current annual production of organic bentonite clay | organoclay is 20,000 metric tons, while refined bentonite production is 15,000 metric tons.

Our ISO 9001 quality system certification and IS014001 environmental management system certification, as well as our own mine with superior ore quality and production of proprietary technology, ensure the long-term quality and supply stability of our Organoclay bentonite | Organophilic clay.

Our mission is to provide users with superior Organoclay bentonite | Organophilic clay and services and to collaborate with them to achieve success and glory.

Internet address: https://www.rheologymodifiers.com/ and email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organoclay | Organophilic Clay CP-2 also named amine treated Bentonite.

In diesel oil based fluids,organophilic clay viscosifier CP-2 are used to increase carrying capacity and suspension properties, providing support for weight materials and improved cutting removal. Organophilic bentonite also aids in filter-cake formation and filtration control.

Properties

Composition Organically modified bentonite clay

Physical appearance Off white to tan free-flowing powder

Moisture content (105℃,2hr) ≤4%

Particle size (<76μm or 200mesh) ≥95%

Specific Gravity 1.6-1.8

Advantages

Effective viscosifier and gellant

Aids control of fluid loss to the formation

Increases emulsion stability

Improves cuttings carrying and hole cleaning capacity

Suspends weighting materials and other solids

Confers temperature stability to the fluid

Application

Base oil:

Diesel Oils

Crude Oils

Mineral Oils

Synthetic Oil

Viscosifying drilling Fluids:

Oil based drilling fluids

Invert emulsion fluids

Workover fluids

Completion fluids

Casing packs

Packer fluids

Spotting fluids

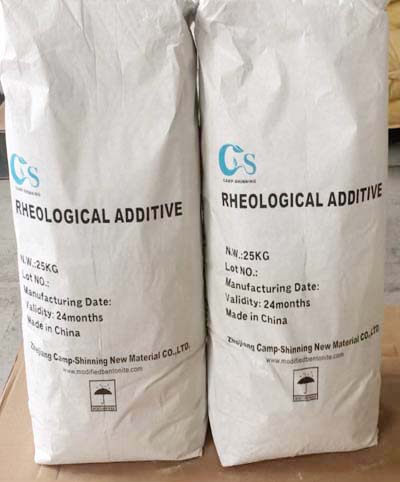

Package

Organoclay | Organophilic Clay CP-2 is packed in 50lb(22.7kg) or 25kg/bag or customized,multi-wall paper sacks or Kraft paper bag with PE liner or customized.

Storage

CP-2 Store in a dry, well-ventilated area with temperature of 0℃-30℃. Keep container closed. The quality guarantee period is 24 months.

Notice

The information on use is based on data which are believed reliable, but any recommendation or suggestion made is without guarantee or warranty, since the conditions of use are outside our control. All products are sold on the conditions that purchasers shall make their own tests to determine the suitability of such products for their purpose and that all risks are assumed by user. We disclaim any responsibility for damages resulting from careless or improper handling or use. Nothing herein is to be taken as permission, inducement or recommendation to practice any patented invention without a license.

Internet address: https://www.rheologicaladditive.com/ and email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Bentonite clay suppliers This article will examine the advantages of bentonite drilling mud suppliers, as well as its properties and applications in drilling fluids. We will also discuss the cost of suppliers of bentonite drilling mud. You should be able to determine whether bentonite drilling mud is suitable for your application after reading this article. Laboratory examinations of bentonite drilling mud manufacturers Bentonite is an important component of drilling mud. Depending on the type and quantity of material used, it possesses various properties. The colloidal properties of bentonite vary from deposit to deposit, for instance. This variation in colloidal properties is correlated with the overburden’s thickness. Its conductivity, viscosity, and gel formation are greatest in eroded outcrops. Additionally, the yield is influenced by the temperature at which bentonite is dried. In the laboratory experiments, pellets of bentonite-quartz were weighed and measured to determine how they altered the filtration and clay swelling properties of drilling mud. The instability of the wellbore is one of the greatest obstacles when drilling through clay-rich rock. To counteract this, oil companies have developed techniques to reinforce the wellbore’s walls. Among these are several shale swelling inhibitors. These studies also examined the composition of drilling fluid based on bentonite. As activators, sodium silicate and sodium hydroxide were utilized. When these two substances were combined, the resulting mixture would solidify, enhancing its cohesive force and shear bonding strength. For evaluating the sealing capacity of drilling fluids, the shear bonding strength between cement and formation is an essential parameter. In addition, they were evaluated in a mud cake solidified with four distinct drilling fluids. In addition, the mechanical properties of solidified mud were analyzed. Characteristics of bentonite Good quality bentonite drilling mud must have a high viscosity and contain a significant amount of montmorillonite, in addition to other clay minerals and non-clay components. Bentonite clay suppliers Several measurements were taken to determine the drilling mud’s gel strength, yield stress, and apparent viscosity. The rheological properties and electrical resistivity were also investigated. These parameters were discovered to have a strong correlation with experimental outcomes. Natural bentonites contain monovalent and divalent cation-based constituents. In general, they are associated with sodium and calcium ions; however, some have mixed interlayer cations. The effects of temperature and salt on the properties of bentonite drilling mud have been studied. At temperatures between 25 and 75 degrees Celsius, it can increase the viscosity of plastic by up to 90 percent. The experimental and computational results demonstrate that a 2%-8% bentonite drilling mud possesses excellent rheological stability. Without bentonite, water-based drilling muds have excellent characteristics, including faster penetration, better hole cleaning, and less formation damage. The rheological properties of these muds, however, are a major concern for mud designers. For oil and gas production, the rheological properties of bentonite drilling mud are crucial. The following table details the various ingredients used to create the mud. Table 1 provides a listing of the quantities of each material. Bentonite applications in drilling fluids Bentonite is a vital industrial mineral that is utilized in numerous industries, including agriculture, energy, and medicine. It improves the filtration efficiency and carrying capacity of water-based drilling fluids when added to drilling fluids. Bentonite is a fine-grained mineral composed of crystallites measuring up to two micrometers in diameter. It reduces the amount of water lost during drilling operations, which can hydrate the borehole and cause the stratum to collapse, when added to water-based drilling fluids. Bentonite clay suppliers Bentonite has several advantages, including being an effective bit lubricant and bore stabilizer. Additionally, it transports suspended particles. However, the greatest difficulty at a drilling site is obtaining sufficient water for drilling. Therefore, it is essential to use a thick, malleable drilling mud that lifts drilling cuttings and prevents damage to the drilling pipe. Due to its superior rheological properties, sodium bentonite is frequently utilized in drilling operations. It forms a viscous, shear-thinning, and low-shear fluid when dissolved in water. The high viscosity indicates a good solids-carrying capacity away from the drill bit, whereas the low viscosity at high shear rates reduces torque requirements. It was also discovered that the thixotropic behavior of bentonite suspensions was advantageous for drilling fluids. When mixing sodium-bentonite with water, it is essential to thoroughly combine the granules. This enhances the rheological properties and mixing stability of bentonite. Typically, bentonite is available as a dry powder or a clear liquid. The dry form is more compact and transportable. Bentonite is utilized in drilling fluids to prevent water from entering the drilled shaft. On the borehole wall, it forms a thick, stable sludge cake, which provides stability. Depending on the ground structure, different concentrations of bentonite can be utilized. Bentonite clay suppliers Bentonite drilling mud price The cost of bentonite drilling mud is proportional to the amount of bentonite utilized. The proper bentonite mixture is required to achieve the desired results. The resulting muck should be thick enough to lift cuttings and not disintegrate into minute particles. Too-thin bentonite can form clumps that are difficult to remove from a borehole. Here, the addition of a polymer is advantageous. Bentonite clay suppliers Occasionally, the oil drilling industry employs a coarser grade of bentonite. Despite the fact that this material lacks the best bentonite properties, it can cost half as much as premium bentonite. However, it expands less than premium bentonite. This material requires four sacks to achieve the same viscosity as premium bentonite.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-180 organoclay is an organo clay rheological additive (modified montmorillonite) designed specifically for use in solvent-based systems

CP-34 organoclay is a modified bentonite that has been specifically designed for use in solvent-based systems.

CP-EDS modified bentonite is a kind of organo clay rheological additive. It is used in systems of medium polarity and high polarity system.

Bentonite clay suppliers,China Organo Bentonite clay suppliers