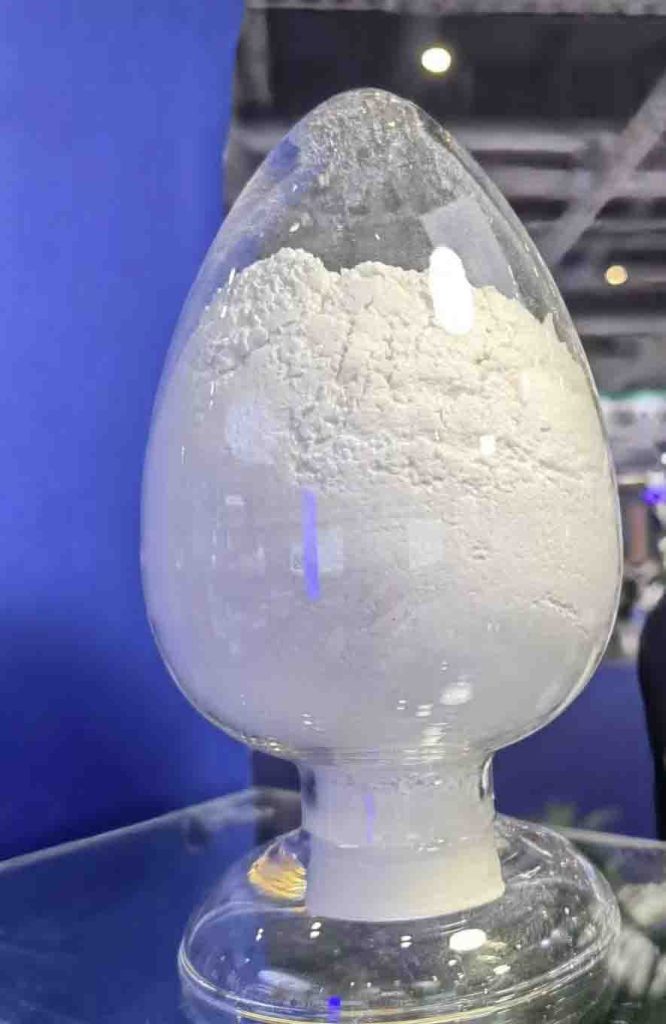

glass beads for sandblasting

Glass Blasting Beads

Glass beads for sandblasting are a spherical filler with a very clear and transparent surface. If you are sandblasting an object, you can use our glass beads in different sizes as an abrasive to achieve your surface treatment requirements. When glass microbeads clean metal surfaces, they have particularly efficient cleaning capabilities and surface smoothness.

At present, glass beads for sandblasting can be applied to casting, soft surface video processing, and surface treatment of metals, components, and stainless steel.

In addition to the above applications, our glass microspheres can also be used as dispersants, grinding media, and fillers in other chemical industries such as coatings and inks. It is also a good reflective material.

What Are Bead Blasting’s Applications?

| Aerospace industry | Remove rust and paint from mechanical components to remove knife marks. |

| Remove scratches on the rubber | Reflective paint for roads |

| Scratch treatment on the surface of stainless steel. | |

| Foundry industry; | Pre processing in the electroplating industry. |

| Semiconductor Industry | Crafts for exterior decoration |

glass beads for sandblasting

Size of glass beads for blasting

Model of Bead blasting glass | Sieve Size (mesh) | Particle Size Range(μm) |

WSL17L# | 20~40 | 425 ~ 850 |

WSL 18L# | 30~40 | 425 ~ 600 |

WSL 19L# | 40~60 | 300 ~ 425 |

WSL 20L# | 60~100 | 150 ~ 300 |

WSL 21L# | 70~140 | 106 ~ 212 |

WSL 22L# | 100~140 | 106 ~ 150 |

WSL 23L# | 100~200 | 75 ~ 150 |

WSL 24L# | 140~200 | 75 ~ 106 |

WSL 25L# | 140~270 | 53 ~ 106 |

WSL 26L# | 200~325 | 45 ~ 75 |

The inherent strength of glass beads allows it to be recycled repeatedly, and it will not affect the surface of the stainless steel when dealing with residual burrs and edges. In other words, glass beads can reduce the impact on other parts of the surface.

Specification of Bead blasting glass

| Specific gravity | 2.4-2.6 g/m3 |

| Stacking density | 1.5g/cm3 |

| Type | Blasting / Shot Peening Media |

| Spherical | |

| Rockwell hardness: | 46HRC |

| Mohs | 6-7 |

| Round rate | 80% |

| Melting point | 710-730 ℃ |

| Index of refraction | 1.5—1.6 |

When using glass beads for sandblasting, you must first select the corresponding size and specification to achieve the desired surface treatment effect. Abrasives used to clean metal surfaces.

Its unique function is to have good burr removal and cleaning functions. Glass yarn is the raw material of glass beads. After high temperature treatment, annealing and elimination of internal stress, it has Ability to prevent breakage.

This kind of glass beads is very environmentally friendly, it can be used repeatedly, and it will not pollute stainless steel and metal parts.

The appearance of glass beads is transparent powder, without bubbles and impurities, the hardness is usually between 6 and 7, and the specific gravity is 2.4-2.6g/cm3.

The compressive strength is greater than 1200N. When choosing glass beads, we recommend that you choose the correct size and hardness. Glass beads are spherical.

It itself is both soft and hard, has a certain mechanical strength, has extremely high chemical stability, can be used repeatedly and is not easily broken.

The advantages of this kind of glass beads as abrasives are that they last longer than ordinary media, have high chemical stability, are not easy to pollute, are very easy to operate and clean, the accuracy will not be affected, and are smooth and impurity-free, with a high finish.

Packing:

Our packaging is divided into 25 kilograms per package and 50 pounds per package, and we can also customize the packaging size according to customer requirements.

Please store in a dry and cool place, avoiding a damp environment, which will help with the long-term storage of glass microspheres.