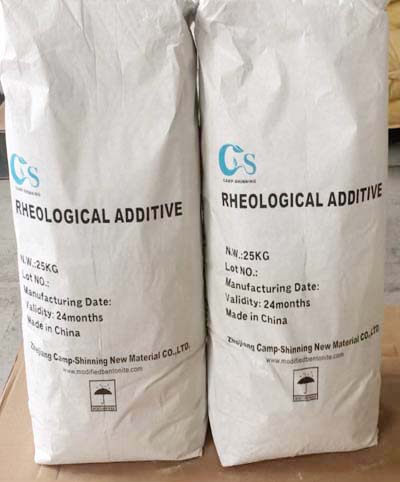

Organo Cays with good bentonite price in China

Whatsapp/Wechat :+86-13185071071

- 20+ Years Experiences

- Strong R & D Team

- ISO Certification & Patents

- Own Raw Bentonite Ore

- Cooperation Experience of the Top 5 Enterprises in the Industry

Good Rheological Properties Organo Cays in Paints & Coatings

Organo Cays : The application range of organic clay bentonite is very wide, and it can be used in anti-corrosion coatings, some car primers, inks, coatings, cosmetics, industrial coatings, interior and exterior wall coatings, repair paint, wooden coatings, and lubricating grease and so on.

Organoclay is mainly to help the above application fields meet the requirements for thixotropy, thickening and anti settling properties.

Organo Cays

CP-10 Organoclay

CP-10 organoclay is a rheological additive made of organoclay. It is used in non-polar to moderately polar aliphatic and other solvent systems

CP-MPZ organoclay

CP-MPZ organoclays is an modified bentonite that is used in solvent and resin systems ranging from non-polar to highly polar.

Organo Cays : Looking for a powder coating raw material that can be used in solvent-based systems? Our Organo Cays is ideal for anyone looking to improve the quality of their coatings, paints, greases, inks, and oil drilling muds. It’s also non-toxic and safe for the environment! Desire: Our organoclay can help you

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

Organoclay For Water Based Coatings

Organo Cays

CP-EW organoclay for water based paint

CP-EW Organoclay for Water Based paint. It is primarily employed in water borne paint systems,such as latex paint. So it is a good water based additive in paints,coatings,grease etc.

CP-EWS Organoclay

CP-EWS Modified bentonite It is employed in a water-borne coatings system. CP-EWS organoclay outperforms CP-EW in terms of thixotropy, transparence, and dispersion.

CP-WBS Rheology modifier

CP-WBS Rheology Modifier is rheological modified bentonite. It is mostly employed in water-borne systems.

The Organoclay bentonite | Organophilic clay -specialized Zhejiang Camp-Shinning New Material CO.,LTD. and Hangzhou Camp-Shinning CO.,LTD. are subsidiaries of Camp-Shinning.

Camp-shinning concentrated on high value-added, high-technology organo bentonite series products, particularly in research, development, manufacturing, and sales of organic (solvent based organoclay) and inorganic bentonite (water based organoclay).

Our Organophilic bentonite clay finds widespread application in oil drilling mud, paint, coating, lubricating grease, adhesive, construction mortar, cosmetics, and waste water treatment, among other applications. A group of world-class professional users and distributors, such as SUN CHEMICAL,,SIEGWERK,LEHMANN &VOsS, and others, have acknowledged our dependable quality.

Current annual production of organic bentonite clay | organoclay is 20,000 metric tons, while refined bentonite production is 15,000 metric tons.

Our ISO 9001 quality system certification and IS014001 environmental management system certification, as well as our own mine with superior ore quality and production of proprietary technology, ensure the long-term quality and supply stability of our Organoclay bentonite | Organophilic clay.

Our mission is to provide users with superior Organoclay bentonite | Organophilic clay and services and to collaborate with them to achieve success and glory.

Internet address: https://www.rheologymodifiers.com/ and email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organo Cays :

Organophilic Clay Production Method

The production of organophilic clays involves the use of a chemical agent to generate a very porous substance. This substance may be ammonium salts or organic amines. Numerous crucial components play a crucial role in the process of preparation.

For the production of Organo Cays , organic amines and ammonium salts are employed.

Organo Cays, such as sodium bentonite, have a high water exchange capacity. They are produced by heating sodium bentonite in the presence of a combination of organic amines and ammonium ions. The end result is an organophilic clay that can be utilized to create mineral oils and paints. The purity of organophilic clays is essential since their use in these domains necessitates a high level of purity.

Hydrophilic fillers are also Organo Cays. The cationic surfactants used to prepare organophilic clay from quaternary ammonium salts. This change also increases the clay’s compatibility with organic liquid media. In addition, these surfactants increase the hydrophobicity of the clay’s interfollicular region.

The amount of applied surfactant determines the spectral hydration of organoclays. The concentration of surfactant also influences the morphologies of organoclays. Additionally, the particle size of bentonite and laterite is diminished.

Ion exchange is also utilized to ease the synthesis of organophilic clays and quaternary ammonium salts.

The dry method of producing Organo Cays differs in key ways from the wet method. Before incorporating the organophilic chemicals, the aqueous clay dispersion is filtered.

Organo Cays generated using the dry method have a lower purity requirement than those manufactured using the water slurry approach. This form of clay is good for thickening paints and mineral oils. In addition, it is beneficial in drilling muds. In such applications, a greater purity level is required to achieve the performance specifications.

How to calculate the correct amount of polymer to add to the raw clay is a big challenge in the production process.

The chemical makeup of the solution.

Before the polymer is utilized, it is dissolved in a solvent. In this solution, clay particles are then dispersed. In a Peter dish, the clay and polymer mixture are then combined and homogenized. The solvent is subsequently evaporated.

During the production of Organo Cays, the chemical composition of the solution is governed by the presence of organic cations and ions. Clay minerals are known to adsorb organic molecules. As such, they are able to remove a variety of pollutants from the environment.

The chemical composition of the solution during the organoclay manufacturing process varies depending on the type of organic compound. Some clay minerals absorb anionic compounds and others are hydrophobic.

Organically modified clays are typically prepared by adding an organic material to a clay system at a high pressure.

The second stage of the process entails the substitution of a cation by clay particles. This process is called a cationic reaction. Organic cations are made from a mixture of organic compounds. The organic material is usually mixed with the clay during the premixing stage. The clay that has been changed organically is then subjected to a high-pressure reaction. The resultant substance is then dried and powdered to a fine powder.

For remediation and treatment of hazardous waters, the nature of the cation employed in organic clay modification is a crucial factor to consider.

The hydrophobicity of the clay that results.

The amount of filler in organophilic clays considerably affects their physicochemical qualities. Due to the rise in filler content and loss in tensile strength, organophilic clays are ideal for applications requiring a high filler content.

However, when a substantial amount of organophilic clay is present, the stability of the drilling muds is compromised. This is due to the adsorption of clay particles by the gasoil-water interface, which may be associated with the saturation of the particles by surfactant molecules.

Organoclays are formed by integrating organic molecules into the mineral structure. In addition to quaternary ammonium cations, they may also include amino acids and vitamins. In the interlayer space, these organic molecules interact with hydrated cations. The resulting organophilic clays exhibit a higher affinity for hydrophobic organic molecules and a lower affinity for hydrophilic organic chemicals.

By increasing its volume, the hydrophobicity of the resulting organophilic clay can be improved. This results in an increase in viscoelasticity and yield stress. The resulting organophilic clays are suited for hydrocarbon-containing drilling muds.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

Grease Grade Organoclay

CP-180 Organoclay

CP-180 organoclay is an organo clay rheological additive (modified montmorillonite) designed specifically for use in solvent-based systems

CP-34 Organoclay

CP-34 organoclay is a modified bentonite that has been specifically designed for use in solvent-based systems.

CP-EDS ORGANOCLAY

CP-EDS modified bentonite is a kind of organo clay rheological additive. It is used in systems of medium polarity and high polarity system.

Drilling Grade Organoclay

CP-992 Organophilic clay

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

CP-982 Organophilic clay

CP-982 Organophilic Clay is an amine treated bentonite with a moderate temperature performance.

CP-150 Organophilic Clay

CP-150 Organophilic Clay is a self-activating organoclay that disperses easily and performs well in diesel, low aromatic mineral oil, modified vegetable oil, and synthetic base fluid formulations.

Send Inquiry Now

Email: [email protected]

Whatsapp/Wechat: +86-13185071071

Organo Cays