organobentonite

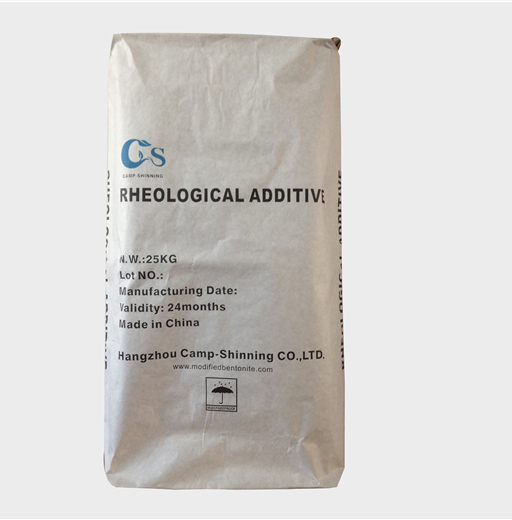

Organobentonite: Advanced Rheological Additive for Industrial Applications In today’s competitive industrial landscape, manufacturers are const

What is a Paint Rheology Modifier?

Coatings are strengthened with the aid of rheology modifiers. They prevent drips from rollers and brushes and decrease sagging on vertical or inclined surfaces. There are three categories of rheology modifiers: hydrophilic, hydrophobic, and nonpolar. In numerous paint formulas, rheology modifiers are employed. Below are the benefits of each option.

Organoclays are used to modify the viscosity of paint and other transparent solutions. The principal component of organoclay is bentonite, a chemically modified type of volcanic ash that can absorb up to seven times its weight in water. Its high absorption rate also makes it a valuable additive for oil-based drilling fluids and as a nucleating agent in polymer chemistry.

There are three different forms of rheology modifiers: precipitated silica, organoclays, and hydrophilic polymers. Each has unique advantages and downsides. Listed below are the fundamental qualities of each type:

Paint and other coating systems use special clays to increase their workability and application. Typically, these clays are mixed with organic thickeners and rheological modifiers. They suppress syneresis during storage and prevent pigment pastes from settling. This makes them an extremely adaptable and valuable component in paint compositions.

Organic rheology modifiers can increase the viscosity of paint and coating compositions by adding resistance to sagging and sedimentation. In addition, they are highly compatible and simple to operate with. Solvent-based and inexpensive paints include these compounds. They are utilized in automobile basecoats and inorganic pigment slurries for paint and coating compositions.

Polyacid dispersants are hydrophobic.

To prevent particle aggregation, a water-based paint recipe may need a hydrophobic dispersion – CP series water based organoclay. This dispersion must also retain a low yield point. To achieve this, the majority of dispersants employ a combination of stabilizing processes. Stabilization can be done through electrostatic repulsion, crowding, or steric contact. The dispersant’s molecular weight also plays an effect. Dispersants with a greater molecular weight have more functional groups. Ultimately, this improves stability by extending the effective charge and steric interaction further away from the particle’s surface.

Without adding water, polyacid dispersants stabilize pigments in a waterborne basecoat. They possess the same hue and vibrancy as solventborne basecoats. Due to these advantages, waterborne basecoats can produce high-quality paints without compromising compatibility with water-based systems. Polyacid dispersants are hydrophobic in paint and a desirable complement to a wide range of formulas.

However, while selecting dispersants for use in coatings, it is essential to consider the final application and formulation chemistry. Dispersants must retain the pigment’s desired solubility and polarity. Additionally, they must be compatible with the pigment’s shape and size. Lastly, they must be compatible with the dispersant used in the paint and possess the necessary level of transparency, gloss, and concealing.

What is Rheology Modifier in Paint

Water paint and acrylic paint are two examples of hydrophobic coatings. Acrylic paint comprises a vinyl-modified epoxyester harze (A) that contains 0-22 grams of vinyl per liter. The other typical hydrophobic coating is urethane, which contains a carboxyl group. Carboxyl-containing vinyl-modified epoxyester harze (A) is a kind of acrylic resin.

https://www.rheologicaladditive.com/

However, organic solvent-containing water-based paints have a dispersion stability issue. When employed in less than 10 percent of the total weight of the paint, these solvents can precipitate. These precipitates have a greater viscosity than water-based paint. Therefore, organic solvents should be utilized in paint compositions with minimal organic solvent concentrations.

Organoclay CP – 10 increases sag resistance.

Organoclay CP – 10 is a common ingredient included in high-concentration paint formulas. It helps to the gloss and brushability of paint. Additionally, its water resistance, antialkaline, and anti-gasoline qualities are improved. This chemically treated surface also strengthens the paint’s resistance to sagging and improves its anti-adhesion and adherence qualities. It belongs to the thixotropant family.

Organoclay CP-40 is a rheology modification bentonite.

Organoclay CP-40 is an associative oil based thickener with excellent flow, gloss, and leveling qualities. It also contributes to the physical qualities of paint compositions. These characteristics include excellent concealing power, water sensitivity, and thixotropy. It is an excellent solution for lowering paint.

As aqueous coatings continue to advance, the additives used to manage viscosity are becoming more complex. In the past, the majority of coatings contained five to seven components and were loaded with glycol ethers. chemical producers have made their additives more effective and environmentally benign. Camp Shinning has describes various thickeners, wetting aids, and dispersing agents used to increase the viscosity and consistency of paint.

Organoclay CP-APA is a rheology modifier used in paint. Due to its low molecular weight, this additive is appropriate for after-correction of paint batches. Three paints were evaluated for low viscosity to determine their effectiveness. To do this, 5 percent water was added to the paint to resemble out-of-specification paint. Cellulosic was then added to the paint to boost its viscosity. After adding the rheology modifier, the viscosity of the paint was measured and compared to that of the conventional paint.

What is Rheology Modifier in Paint?

Rheology modifiers are essential coating additives. They help achieve the correct viscosity and regulate the paint’s shelf life, ease of application, wet edge, and sagging. Choosing the proper one for your project might be difficult, especially when considering the restrictions pertaining to volatile organic compounds, aqueous, and solvent-borne coatings. Below, we examine the benefits and drawbacks of several rheology modifiers.

CP-APA RHEOLOGY MODIFIER decreases sag resistance

A sagging resistance test assesses a paint’s ability to withstand bending. It is determined by the viscosity of a coating; the higher the viscosity, the stronger the resistance to sagging. The testing techniques for this attribute are normally standardized, and two to five determinations are necessary for repeatability.

CP-APA RHEOLOGY MODIFIER has been evaluated in low-odor paints. Its odorlessness is an extra bonus. It has a comparable rheological characteristic to ordinary vinyl acrylic. Even when the colorants are predispersed, it can retain the paint’s viscosity. Its low shear resistance decreases sagging and enhances the scrub qualities of paint.

Organobentonite: Advanced Rheological Additive for Industrial Applications In today’s competitive industrial landscape, manufacturers are const

CP-2 Organobentonite for Oil drilling Mud for diesel system CP-2 Organobentonite CP-180 organoclay is an organo clay rheological additive (modified mo

+86-13185071071 (Whatsapp) paint thickener 20+ Years Experiences Strong R & D Team ISO Certification & Patents Own Raw Bentonite Ore Cooperati

+86-13185071071 (Whatsapp) thixotropic agent 20+ Years Experiences Strong R & D Team ISO Certification & Patents Own Raw Bentonite Ore Coopera

+86-13185071071 (Whatsapp) suspending agent 20+ Years Experiences Strong R & D Team ISO Certification & Patents Own Raw Bentonite Ore Cooperat

+86-13185071071 (Whatsapp) anti settling agent in paint 20+ Years Experiences Strong R & D Team ISO Certification & Patents Own Raw Bentonite